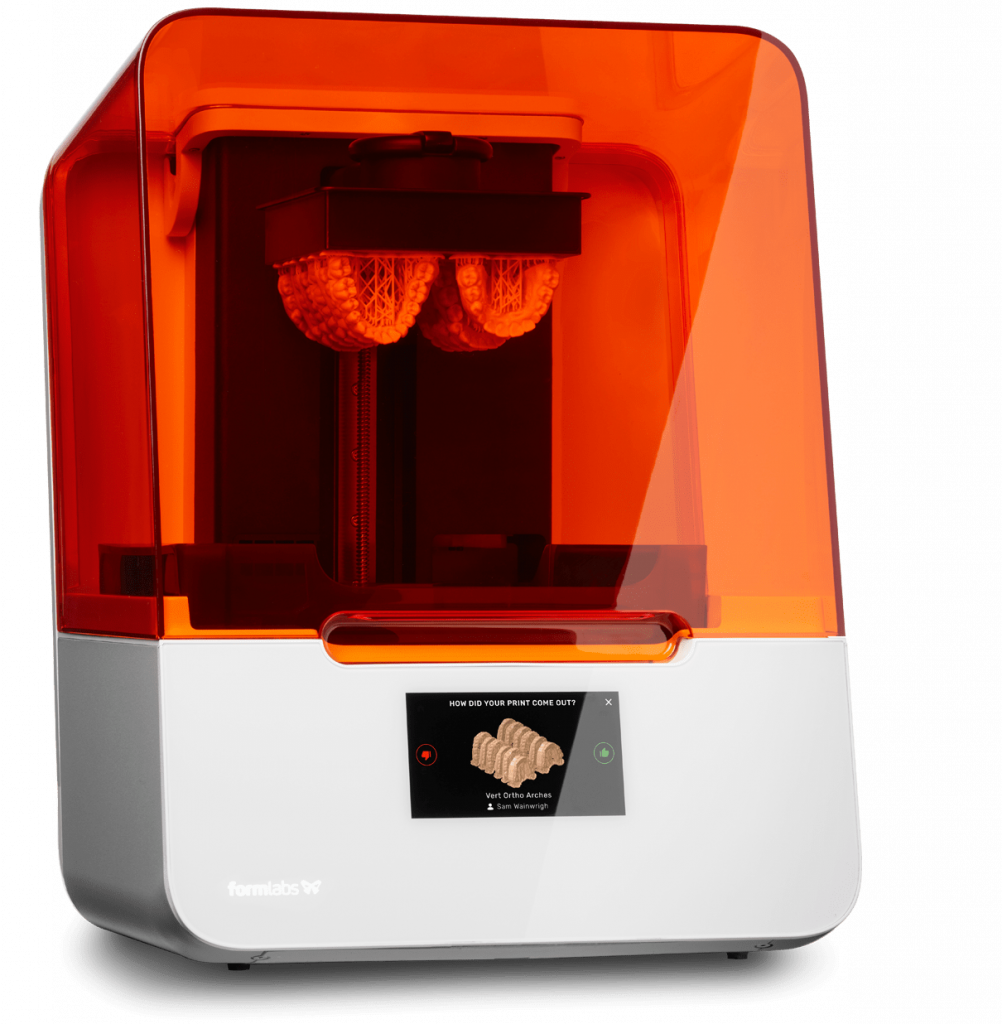

Form 3B

More Smiles, All Around

The Form 3B is an advanced desktop 3D printer optimized for biocompatible materials. Our precise, reliable ecosystem takes the guesswork out of dental fabrication so faster workflows are just a few clicks away.

Product Demo: Form 3B Dental 3D Printer

In this webinar, Sam Wainwright, dental product manager at Formlabs, will walk through the new Formlabs Dental business unit and the Form 3B ecosystem, optimized to produce high quality dental parts and biocompatible appliances, including the step-by-step workflow for using the Form 3B.

The Easy Choice for Digital Appliance Production

Reclaim your time and produce parts you’ll be proud to deliver, without the hassle or prohibitive costs. Formlabs brings unprecedented reliability, quality, and ease of use, with validated workflows tested by a team of dental experts.

1. Scan

Collect patient anatomy digitally using an intraoral scanner. Send scans to the lab with a digital prescription or to a design station.

2. Design

Import scan data into dental CAD software to design treatments virtually, or send scans directly to print preparation.

3. Print

Import the designed CAD files into PreForm print preparation software for print setup and send them easily to a Formlabs printer.

4. Prepare

Wash, dry, and post-cure printed parts. These parts can then be used intraorally or be used to produce various indications.

The Next Generation of Dental 3D Printing

XY Resolution:

25 microns

Advanced Low Force Stereolithography (LFS)™ technology uses a flexible resin tank and a custom-designed, user-replaceable Light Processing Unit (LPU) to produce consistent, accurate prints. Reduced peel forces lead to incredible surface finish and part clarity, right off the printer.

Built for Production

Build Volume:

14.5 × 14.5 × 18.5 cm

5.7 × 5.7 × 7.3 in

Print 2-3 times more parts in a single build compared to small build plate DLP printers to spend less time handling your printer and more time on high-value tasks. Production environments can see 55% less labor time and costs compared to DLP. A modular ecosystem allows for unmatched consistency, scalability, and redundancy.